shopail.com

0.8mm 1.0mm 20g 50g 100g Soldering Tin Wire Tin Melt Rosin Core Solder Soldering Wire Roll No-clean FLUX 2.0%

0.8mm 1.0mm 20g 50g 100g Soldering Tin Wire Tin Melt Rosin Core Solder Soldering Wire Roll No-clean FLUX 2.0%

Couldn't load pickup availability

Specifications

Diameter:0.8mm/1.0mm

Material: Tin alloy+plastic

Size: The diameter of 20g model is about

4.5cm; The diameter of the 50g model and the 100g model is about 5.5cm

Category: Solder wire

Package includes: 1 * roll of solder wire

Description

1. High purity raw materials: Our soldering wire is made of high-quality and high-purity soldering raw materials, adding 2.2% special flux to ordinary tin alloy. During the welding process, high-purity materials help slow down oxidation, thereby accelerating the tin flow rate and minimizing residual impurities

2. Durable and sturdy: Ensure sufficient quantity of solder wire per roll. The tin wire will not tangle, and the rosin inside the tin wire is evenly distributed, ensuring good continuity. When you use our soldering wire, you will find it sturdy and durable. It has good extensibility, melting, conductivity, and thermal conductivity.

3. Green and fresh odor: Made of environmentally friendly materials, without irritating odor, fresh and natural. Designed specifically for welding, it minimizes splashing and smoke, making it the preferred choice for environmentally conscious individuals.

4. Multifunctional use: Easy to use, you can choose materials according to different needs. Aluminum wire has a wider range of applications and can be welded to various metal materials, such as galvanized pipes, nickel plated pipes, iron plates, stainless steel plates, copper plates, aluminum plates, etc., quickly. Suitable for welding some stainless steel nickel and copper materials. It can be used anytime, anywhere, even at low temperatures, to meet all your needs.

Lighter Welding Wire Usage Tutorial

Lighter welding wire is mostly low-temperature flux-cored wire, suitable for repairing small metal parts. The operation steps are simple, and the specific tutorial is as follows:

1. Pretreatment: Grind the welding area with sandpaper to completely remove the paint layer, oxides and oil stains on the surface to avoid affecting the welding firmness; if welding small parts (such as wires), first twist and fix the ends to be welded to prevent displacement during welding.

2. Heating and Welding: Hold a windproof lighter, evenly heat the welding area with the outer flame (the area with the highest temperature) of the flame, and at the same time gently scratch the end of the welding wire close to the heating point. When the temperature reaches above 360℃, the welding wire will melt by itself. Let the molten liquid flow into the weld seam or joint evenly to ensure complete coverage.

3. Cooling and Forming: After the weld seam is full, first remove the lighter, keep the welded part still, and let it cool naturally. If rapid cooling is needed, apply a wet towel to the surrounding area lightly. No additional treatment of residues is required after cooling.

Notes: It is only suitable for repairing thin parts and cannot replace an electric welding machine; avoid burning the same position with the flame for a long time during welding to prevent damage to the welded part, and do a good job of hand protection at the same time.

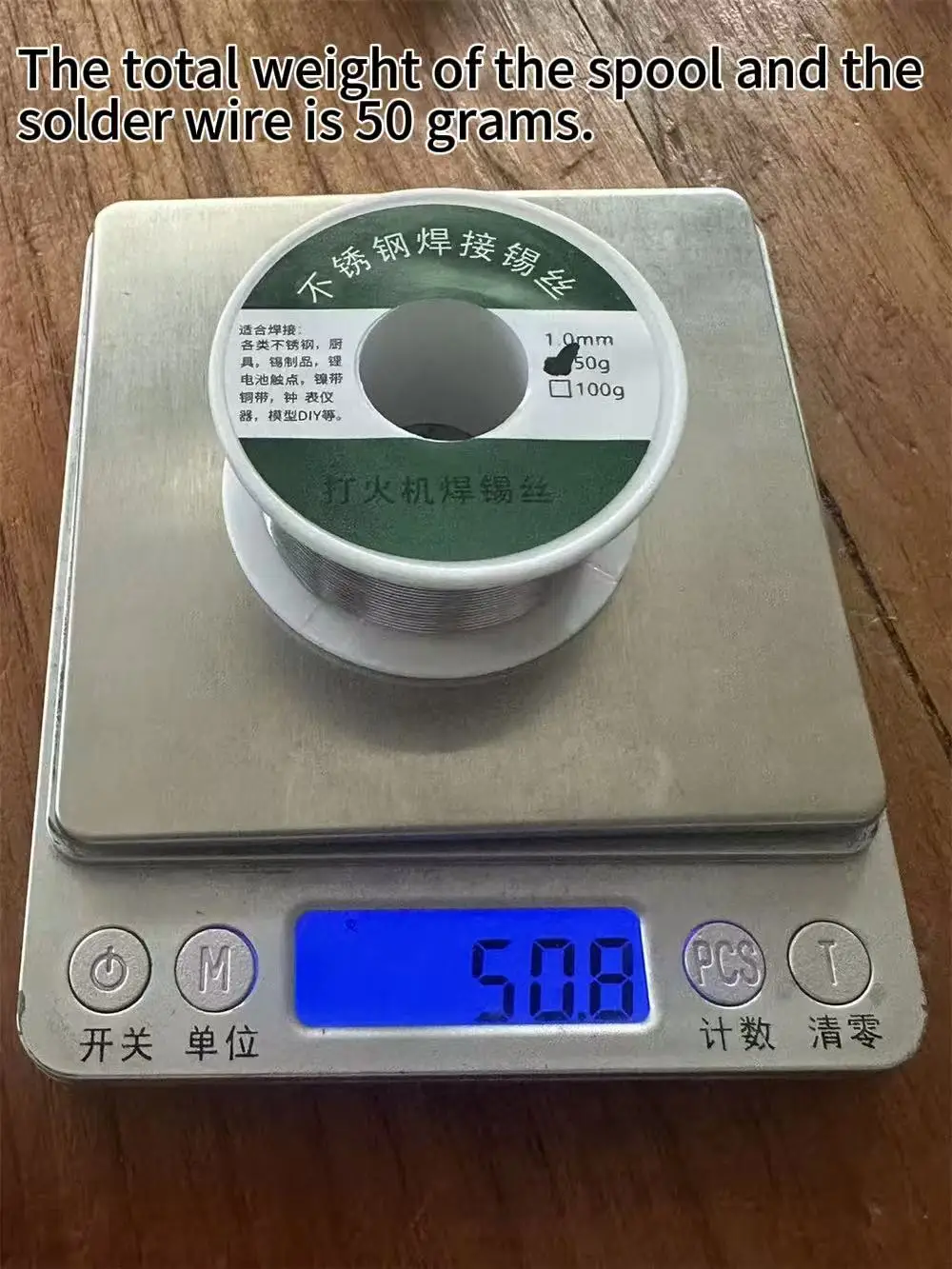

The product weight includes the solder wire and the spool

Share